- Email: info@sinoshred.com

- Tel: +86 18539912790

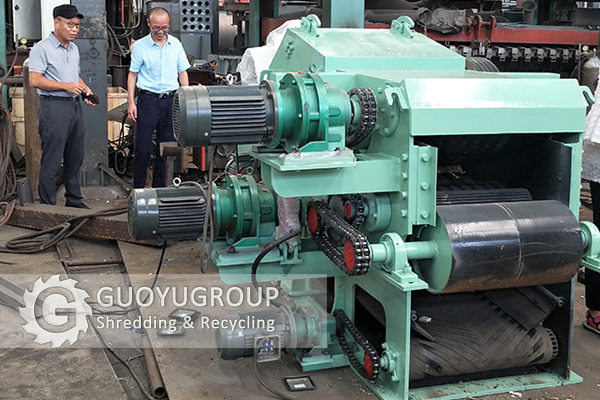

Drum Wood Chipper GY-216/218

Wood Chipper Machine For Sale (Drum style, GY-216/218)

1- Wood Chipper Machine: It's a professional tree wood chipper, which can be used to cut non-wood raw materials (such as sugarcane, reed, bamboo, etc.). It's drum style wood chipping machine. After processing by this wood chipping machine, the raw wood material becomes the small wood chips of a certain specification, which can be used as the raw material of chipboard, medium density board, fiber board and so on. It's a perfect industrial wood chipper (also known as a best helpful industrial wood shredder) in the market. Low investment with high money return!

2- Application Materials: Processing residual materials (such as branches, branches, sheet, slats, round wood core, waste veneer, waste wood, etc.)

3- Power: 55kw-110kw | Capacity: 5-10t/h

| Wood chipper Machine | GY-216 | GY-218 |

| Feeding port size | 230*590mm | 300*780mm |

| Fuel types | Motor | Motor |

| Blade quantity | 2 pieces | 2 pieces |

| Blade roller speed | 590r/min | 650r/min |

| Outcome size | ≤7cm | ≤7cm |

| Capacity: | 5--7t/h | 8--10t/h |

| Main motor power | 4-55kw | 4-110kw |

| Feed motor power | (3-4)*2kw | (4--5.5)*2kw |

| Oil pump motor power | 1.5kw | 1.5kw |

| Conveyor motor power | 3kw | 4kw |

| Weight | 5t | 7 ton |

| Dimensions: L*W*H (mm) | 2600 *1500*1350mm | 3200*2500*1600mm |

Mobile Wood Chipper Machine For Sale

Click To See Large Integrated Drum Wood Chipper For Sale (Power: 110kw-315kw | Capacity: 15-40t/h)

Stationary Integrated Wood Chipper

Tracked Mobile Integrated Wood Chipper

Rubber Tyred Integrated Wood Chipper

Garden Branch Wood Chipper (22kw-75kw | Capacity: 2-5t/h)

Working Principle of Drum Wood Chipper Machine

· Working principle: the wood is fed by the feed inlet. When the wood touches the cutting blade, it will be cut by the high-speed rotation of the cutting disc. The wood is sent out by the high-speed steam flow generated by the blades of the cutting disc in the cutting room.

· Structure composition: drum chipper consists of body, cutter roller, upper and lower feeding mechanism, feeding device, hydraulic system and other parts.

· Its frame is welded with high strength steel plate, which is the supporting foundation of the whole drum chipper.

· Two sets of flying knives are installed on the cutter roll, and they are fixed on the cutter roll through the pressure block with specially manufactured bolt.

· According to the different thickness of the cutting material, the upper feeding roller assembly can float up and down within a certain range by means of hydraulic system.

· Cut down the qualified sheet through the screen hole through the bottom discharge, large sheet will be cut in the machine.

· Drum chipper hydraulic system: from hand oil pump to oil cylinder, can start the housing, easy to change the blade, when maintenance can lift up feed roller assembly, easy to adjust the fly blade, the clearance of the bottom knife and the disassembly of the comb plate.

What Kind Wood Products Can Be Processed?